H2S Scavenger

H2S A-plus 100 in Refining

Introduction

Oil On Spec has brought to market the product A-plus 100; an innovative non-amine/nonaldehyde H2S scavenger for crude oil and refined oil products applications. A need was identified to reduce fouling created by amine based scavengers in refineries, production streams and oil terminals.

Reaction Overview

R(A-Plus 100) + H2S R’SO4-2 + H2O

– A-Plus 100 will chelate the H2S molecules and turn them into an aqueous, non-toxic sulphate

salt

– The heavier sulphate salt molecule will drop into produced water stream

– Reaction is fast and irreversible.

– Active component of the is stable up to 300°C.

– A-Plus 100 will react instantaneously with H2S once contact is made.

– A-Plus 100 will also react with lower chain mercaptans.

– Mercaptan reaction time may take up to 24 hours depending on mercaptan types.

– A-Plus 100 will react with carbon dioxide

– A-Plus 100 will not react with double bonded mercaptans

Separation

– The density of the active A-Plus 100 components is 1.1-1.2 kg/l.

– Promotes efficient separation from crude oil within 12-24 hours.

– Washes out in the desalter.

The high specific gravity of this product is designed to promote efficient separation from the crude oil

when transferred into separators or storage tanks. Complete separation is usually achieved within 12-24

hours depending on the viscosity of the hydrocarbon being treated.

Any A-Plus 100 left within the crude oil, should wash out in the desalter. The water soluble sulphate salts

of the reacted product are typically separated from the crude oil at this stage of the refining process.

Waste Water Treatment Plant

Background

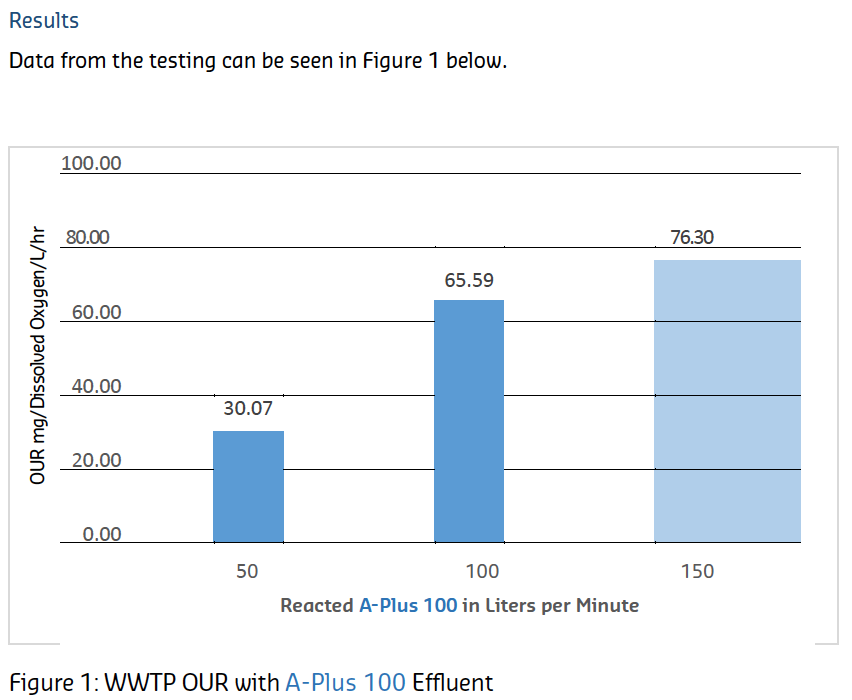

A-Plus 100 will react into a stable non-hazardous sulphate salt (SO4-2). Lab testing has shown that Oxygen

Uptake Rates (OUR) in a waste water treatment plant (WWTP) will increase as a function of Reacted A-Plus.100.

Water samples from a refinery’s WWTP were obtained and dosed to mimic a scenario where A-Plus 100 would enter the WWTP at 50, 100 and 150 liter per minute.